Discover the top 7 oil seal manufacturers in 2026. Compare quality, materials, pricing, and OEM/ODM options to choose the best supplier for your equipment needs.

What to Look for in a High-Quality Oil Seal Manufacturer

Whenever I evaluate high-quality oil seal manufacturers, I approach the process the same way I choose a mechanic I trust with my car. I want someone who understands the details, delivers consistent workmanship, and never cuts corners.

Oil seals look simple at a glance, but in reality, they carry the responsibility of keeping an entire machine clean, pressurized, and leak free. A bad seal can shut down a production line, damage an engine, or cost a company weeks of downtime.

That is why choosing the right manufacturer is not just a procurement decision. It is a risk management strategy. Below are the checkpoints I always rely on when comparing global oil seals suppliers and lip seal manufacturers.

1. Material Technology: NBR, FKM, PTFE, HNBR, ACM

The first thing I inspect is material technology because a seal is only as good as the rubber compound behind it. I like to think of seal materials the way I think about choosing tires. You would not drive a sports car with winter tires in the desert, and you would not take slick race tires onto snow. Oil seal performance depends heavily on the environment.

Here is how I evaluate each material:

- NBR provides cost-effective resistance to oil and fuel for general applications.

- FKM handles high temperatures and aggressive

- PTFE offers extremely low friction and longevity for high-speed or precision machinery.

- HNBR adds strength and weather resistance for industrial equipment.

- ACM delivers excellent heat resistance for engines and automatic transmissions.

High-quality oil seal manufacturers usually have in-house chemists or long-term partnerships with rubber compound developers. If a supplier cannot explain their material grade differences, I immediately consider it a red flag.

2. Manufacturing Standards and Certifications (ISO 9001, IATF 16949, RoHS)

I always look for certifications because they tell me whether a manufacturer is disciplined, audited, and accountable. When I see ISO or IATF certifications, I know the company follows strict guidelines that guarantee consistency.

The certifications that matter most include:

- ISO 9001 for general quality management

- IATF 16949 for automotive-grade certification

- RoHS compliance to ensure material safety and environmental responsibility

Top oil seals suppliers openly display these certifications because they know buyers look for them. If a manufacturer hesitates to share documentation, it usually means their processes are not as controlled as they claim.

3. Precision Engineering and Production Capabilities

Oil seals may be small components, but they solve big problems. Precision is everything. When I tour a factory or review engineering documents, I look for machining accuracy, molding precision, and stability in production batches.

Key capabilities I look for include:

- Micron-level tolerances in metal casing and rubber molding

- Automated trimming systems for consistent lip profiles

- Advanced bonding techniques between rubber and metal

- In-house CNC machining to customize seal dimensions

- Rigorous leak testing and pressure cycling

Reliable lip seal manufacturers are obsessive about precision because tiny variances can lead to leaks, contamination, or rapid wear.

4. OEM and ODM Support and Custom Seal Solutions

Many of the best oil seal manufacturers do more than produce catalog items. They help engineers solve problems. I always pay attention to whether they provide OEM or ODM services because it shows they understand the real-world challenges of integrating seals into engines, gearboxes, pumps, and hydraulic systems.

The most valuable support usually includes:

- Custom material formulation

- Tailored lip geometries

- Prototype development

- Rapid tooling and sampling

- Co-engineering with the client’s R & D team

When a manufacturer is willing to put engineers and production planners at the same table, that is when truly high-performance seals get built.

5. Durability, Temperature Resistance, and Pressure Ratings

A great oil seal does not simply survive. It thrives under stress. When I assess durability, I look at performance data under different temperatures, contamination levels, and pressure conditions. I picture the seal like a goalkeeper who cannot afford to let anything get past.

Key performance factors include:

- Maximum and minimum operating temperature

- Media compatibility with oils, fuels, coolants, and chemicals

- Dynamic vs. static sealing capabilities

- Acceptable pressure thresholds

- Wear resistance under high RPM or constant rotation

Reputable oil seals suppliers always provide detailed test reports. If the manufacturer cannot show real numbers, I do not consider their seals ready for demanding environments.

6. Supply Stability, Lead Times, and Global Distribution

Even the best oil seal is useless if you cannot get it on time. Many engineers overlook supply chain reliability, but I treat it as a crucial selection factor. I want manufacturers who can scale production, support long-term orders, and deliver globally without constant delays.

Here is what I check:

- Average lead time

- Stock levels for common sizes

- Ability to support urgent production increases

- Global warehouse locations

- Logistics partnerships for fast shipping

- Clear communication on delays or material shortages

Reliable supply chains separate good oil seal manufacturers from truly world-class ones. The best suppliers maintain stable production even when raw material markets tighten or demand spikes.

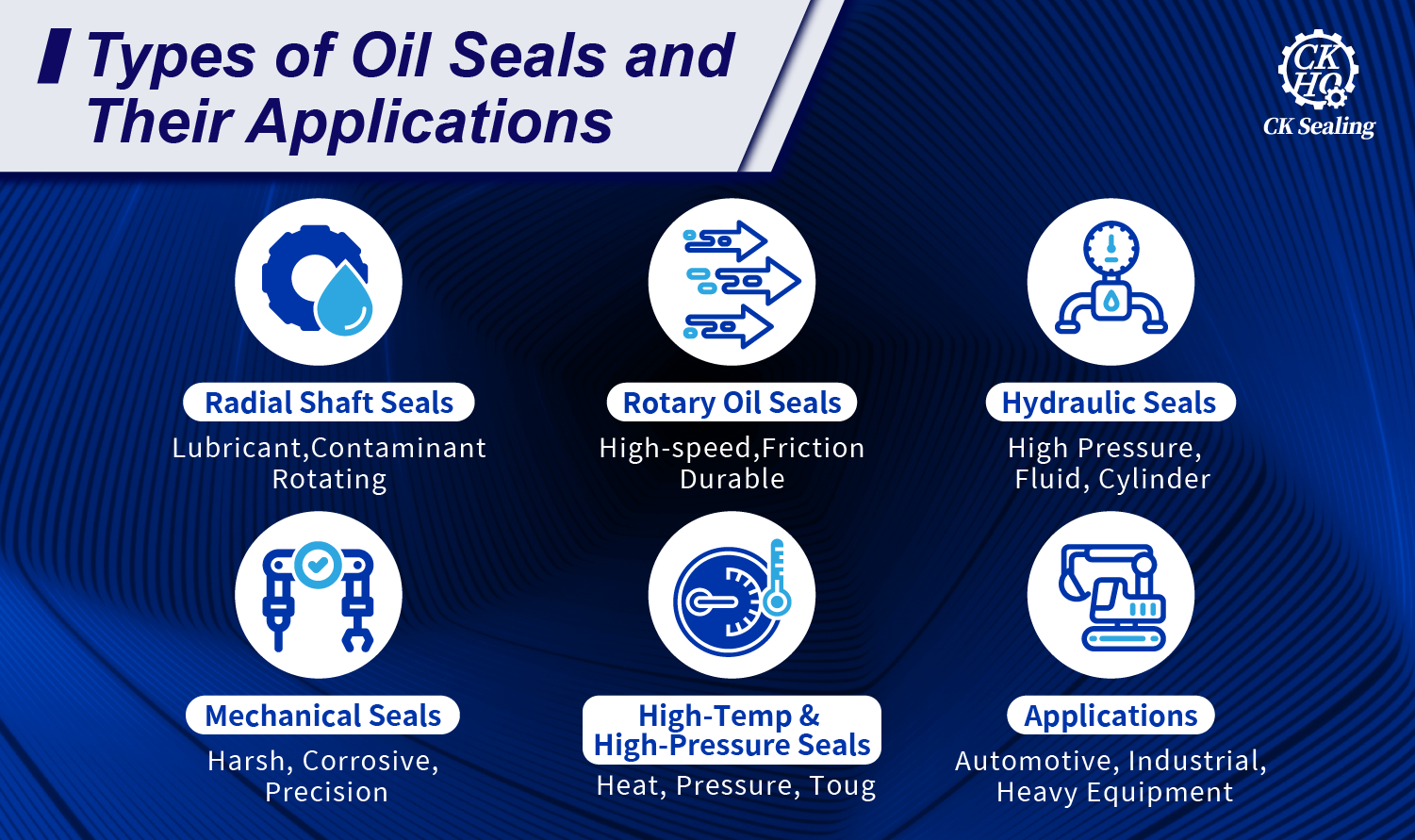

Types of Oil Seals and Their Applications

Whenever I help a client choose the right type of oil seal, I often compare the process to choosing the right tool from a toolbox. You would not use a hammer to tighten a screw, and you would not use a screwdriver to cut metal. Oil seals work the same way. Each type is designed for a specific job, environment, and level of mechanical stress.

Understanding the differences makes it much easier to match the right seal to the right machine, whether you are working with automotive engines, industrial pumps, hydraulic cylinders, or heavy equipment. Below are the types I evaluate most often when comparing products from oil seal manufacturers and oil seals suppliers worldwide.

Radial Shaft Seals

Radial shaft seals are the everyday heroes in sealing technology. When I inspect machinery, I see them almost everywhere, from engines to gearboxes to industrial motors. Their main job is simple but critical. They keep lubricants inside and contaminants outside while a shaft rotates.

Typical features include:

- A flexible sealing lip that follows the shaft surface

- Metal or rubber-reinforced casing

- Ability to handle moderate speeds and pressures

Reliable lip seal manufacturers usually specialize in radial shaft seals because they are used across multiple industries. These seals are essential for preventing oil leakage in rotating shafts found in automotive drivetrains, small engines, and factory equipment.

Rotary Oil Seals

Rotary oil seals are built for applications that involve continuous or high-speed rotation. I like to think of these seals as marathon runners. They need stamina, smoothness, and heat tolerance to perform without breaking down.

Common applications include:

- Electric motors

- Pumps

- Gear reducers

- High-speed transmission components

Top oil seal manufacturers often enhance these seals with PTFE or advanced elastomers to reduce friction and increase service life. These seals are especially valuable in industrial machinery where constant rotation creates heat and mechanical wear.

Hydraulic Seals

Hydraulic seals are the powerlifters of the sealing world. They must contain extreme pressure and keep hydraulic fluid from escaping even under intense mechanical force. I see these seals used in systems where power and precision matter most.

Hydraulic seals are widely used in:

- Construction equipment

- Forklifts

- Injection molding machines

- Hydraulic cylinders and actuators

Oil seals suppliers usually carry a wide range of hydraulic sealing components, including piston seals, rod seals, wipers, and guides. Without proper hydraulic seals, pressure drops, performance declines, and equipment becomes unsafe.

Mechanical Seals

Mechanical seals are used when a standard elastomer lip is not enough. I often describe them as the engineers of the sealing world because they use a combination of polished faces, springs, and fluid pressure to create an extremely tight seal.

These seals are essential for:

- Industrial pumps

- Chemical processing equipment

- Marine shafts

- High-speed compressors

Mechanical seals are preferred in harsh or corrosive environments where standard lip-based designs simply cannot survive. Many high-end oil seal manufacturers specialize in producing mechanical seals for industries that require near-zero leakage.

High-Temperature and High-Pressure Oil Seals

When I work with engines, turbines, or heavy industrial systems, I often need seals that can tolerate extreme heat or crushing pressure. These are the seals that behave like specialized protective gear. They are designed not only to survive, but to stay fully functional in tough environments where traditional materials would fail.

Key use cases include:

- Turbochargers

- High-pressure pumps

- Steel manufacturing lines

- Heavy-load industrial gearboxes

These seals are usually made with advanced materials such as FKM, PTFE, HNBR, or custom blends. The best lip seal manufacturers provide detailed temperature and pressure ratings because professionals rely heavily on these numbers when specifying parts.

Automotive, Industrial Machinery, and Heavy Equipment Applications

Oil seals play a critical role in almost every mechanical system I encounter. Their applications stretch across multiple industries, and the requirements change dramatically depending on the environment.

Here is where oil seals are most commonly used:

Automotive

- Engine crankshafts

- Camshafts

- Axles and wheel hubs

- Power steering systems

- Automatic transmissions

Most automotive-focused oil seal manufacturers follow strict IATF standards to ensure consistent durability.

Industrial Machinery

- Pumps

- Gearboxes

- Conveyors

- Electric motors

- Compressors

Industrial equipment demands seals that resist continuous operation, contaminants, vibration, and fluctuating loads.

Heavy Equipment

- Excavators

- Bulldozers

- Mining machinery

- Hydraulic cylinders

- Agricultural equipment

Oil seals suppliers for heavy industries must offer materials that handle dirt, shock, temperature swings, and extremely high pressure.

TOP 7 Oil Seal Manufacturers in 2026

Key comparison points for CK Sealing vs competing oil seal makers

- Product scope & specialization

- Application industries & segments

- Product portfolio depth

- OEM / ODM capability & export markets

- Certifications & quality systems

- Years of experience & company scale

- Material technologies & product performance

- Target markets (automotive vs general industry)

- Customization & engineering support

| Brand | Country / Region | Core Product Focus | Main Application Industries | Product Portfolio Breadth | OEM / OE Strength* | Typical Positioning / Notes |

| CK Sealing | Taiwan | Oil seals & molded rubber sealing parts | General industry (pumps, gearboxes, motors), agri / mining / construction machinery | Mainly rotary shaft / oil seals + related rubber parts | Medium (export to 50+ countries) | Flexible Taiwanese OEM/ODM partner; good value and engineering support for industrial uses |

| Freudenberg Sealing Tech. | Germany | High-performance sealing systems & materials | Automotive, e-mobility, energy, heavy industry | Very broad: rotary, static, fluid power, e-mobility | Very High | Global engineering partner for demanding / future-oriented sealing applications |

| Trelleborg Sealing Sol. | Sweden | Polymer-based critical sealing solutions | Aerospace, automotive, general industry, medical | Extremely broad: O-rings, rotary, hydraulic, static | Very High | Wide portfolio + strong custom engineering; good for multi-industry global programs |

| SKF | Sweden | Radial shaft seals & system seals | Rotating equipment, power transmission, automotive | Strong in rotary & shaft seals + system solutions | High–Very High | Ideal when combining bearings + seals from one global supplier |

| Parker Prädifa | USA / Global | Hydraulic / pneumatic & industrial seals | Fluid power, machinery, chemical, food & beverage, industry | Broad: O-rings, rod/piston seals, static seals, gaskets | High | Engineering-driven sealing + materials within Parker’s motion & control ecosystem |

| KACO GmbH | Germany | Radial shaft & dynamic engine / driveline seals | Automotive engines, gearboxes, pumps, axles | Focused but deep in automotive shaft & dynamic seals | High | German specialist for powertrain sealing; strong in ICE and transmission applications |

| Hallite Seals | UK / Global | Hydraulic cylinder seals & wipers | Fluid power, mobile hydraulics, industrial hydraulics | Focused on hydraulic/pneumatic seals & bearings | High | Go-to brand for premium hydraulic cylinder sealing packages |

CK Sealing Corporation

CK Sealing Corporation is a Taiwan-based manufacturer specializing in oil seals for the automotive and vehicle transportation industry, with transmission oil seals for automatic and manual gearboxes as its flagship and highest-volume products.

The company’s sealing solutions are widely adopted by industrial OEs and automotive aftermarket customers, where reliability and long-term performance are critical.

Designed specifically for real-world vehicle transmission environments, CK Sealing’s transmission oil seals are built to endure sustained high temperatures, high pressures, and continuous rotational stress inside gearboxes.

These seals not only prevent oil leakage but also contribute to smoother power transmission, improved drivetrain efficiency, and extended service life, key performance factors in modern automotive systems.

With more than 30 years of specialized manufacturing experience, CK Sealing delivers customized OE/ODM sealing solutions to customers in over 50 countries worldwide. While automotive applications such as engines, automatic transmissions, and gearboxes remain its core focus, the company’s oil seals are also trusted in industrial pumps, motors, automation equipment, agricultural machinery, and construction vehicles operating under harsh conditions.

From a supplier evaluation perspective, CK Sealing is recognized as an engineering-driven Taiwanese partner with deep expertise in vehicle transmission oil seals, offering flexible design collaboration, stable quality control, and competitive value.

This combination makes the company a reliable choice for automotive and industrial customers seeking long-term sealing performance and manufacturing consistency.

WebSite:https://cksealing.com/

Freudenberg Sealing Technologies

Freudenberg Sealing Technologies (FST) is the sealing arm of the German Freudenberg Group and describes itself as a global leader in highly demanding sealing technologies.

Freudenberg develops and supplies high-performance seals for industries such as automotive, electric mobility, renewable energy, mechanical engineering and general industry. Its portfolio covers a wide variety of seal types and engineered materials, often focused on applications requiring long service life, high pressure, aggressive media resistance or extreme temperatures.

From a buyer’s perspective, FST is a tier-one engineering partner for complex sealing challenges, especially in future-oriented fields like EV drivetrains, hydrogen systems and other demanding applications.

WebSite:https://www.fst.com/

Trelleborg Sealing Solutions

Trelleborg Sealing Solutions is a business area of the Trelleborg Group and is described as a leading global supplier of polymer-based critical sealing solutions and components for aerospace, automotive and general industrial markets.

Its seals site shows a very broad product portfolio: O-rings, hydraulic seals, rotary shaft seals, oil seals, static seals, pneumatic seals, mechanical face seals and more, plus engineered molded parts, flat gaskets and medical sealing solutions.

Trelleborg is typically chosen when customers need a wide-ranging, global sealing partner capable of supporting multi-industry programs with both catalog parts and highly engineered custom solutions.

WebSite:https://www.trelleborg.com/en/seals

SKF Seals

SKF is best known as a bearing manufacturer, but it also has a substantial seals business. CR Seals (formerly Chicago Rawhide) is the SKF brand for power transmission shaft seals and radial shaft seals, which have been setting performance and service life standards in industrial and automotive markets.

SKF’s seals business covers industrial seals and automotive seals for engines, drivelines, suspensions and wheel-end applications, including radial shaft seals and rotary seals that work together with SKF bearings in complete system solutions.

For customers, SKF is attractive when they want to integrate bearings and seals from a single global supplier, especially in rotating equipment and power transmission applications.

WebSite:https://www.skf.com/group/products/seals

Parker Prädifa

Parker Prädifa is the sealing technology division of Parker Hannifin, providing a wide portfolio of standard sealing elements and custom sealing systems.

The division supplies O-rings, rod and piston seals, static seals, gaskets and application-specific sealing solutions for industries like general machinery, chemical processing, facility engineering, food & beverage, and more. Parker emphasizes engineered sealing materials designed for demanding media, pressure and regulatory requirements.

In a vendor matrix, Parker Prädifa is strong as a global engineering partner for fluid power and industrial sealing, especially when the same group is also supplying hydraulics, pneumatics and motion control components.

WebSite:https://www.parker.com/

KACO

KACO is a German sealing systems specialist whose products fulfill a wide variety of sealing tasks in international automotive construction. Their dynamic seal portfolio includes radial shaft seals, axial seals, piston seals and rod seals.

KACO highlights spring-loaded radial shaft seals and PTFE radial shaft seals as robust, individual sealing solutions for internal combustion engines, gearboxes, oil and fuel pumps, steering gears and axles. Materials listed include AEM, ACM, FKM, HNBR, NBR and PTFE, demonstrating strong compound expertise for powertrain applications.

For buyers, KACO is a go-to brand when they need high-quality automotive shaft seals with German engineering, especially in engine and transmission projects.

WebSite:https://kaco.de/en/

Hallite Seals International

Hallite is a leading manufacturer of fluid power hydraulic and pneumatic seals, wiper seals, bearings and custom high-performance rubber and plastic parts.

The company focuses heavily on hydraulic cylinder sealing systems, offering rod seals, piston seals (single and double acting), vee pack sets, wiper seals, rod buffer seals, static seals and related products for medium to heavy-duty hydraulic applications.

Hallite is usually selected by OEMs and cylinder manufacturers who need premium, proven sealing packages for hydraulic and pneumatic systems, and who value a global support network and strong application engineering.

WebSite:https://hallite.com/

The Complete List: TOP 7 Oil Seal Manufacturers

- CK Sealing

- Freudenberg Sealing Tech

- Trelleborg Sealing Sol

- SKF

- Parker Prädifa

- KACO GmbH

- Hallite Seals

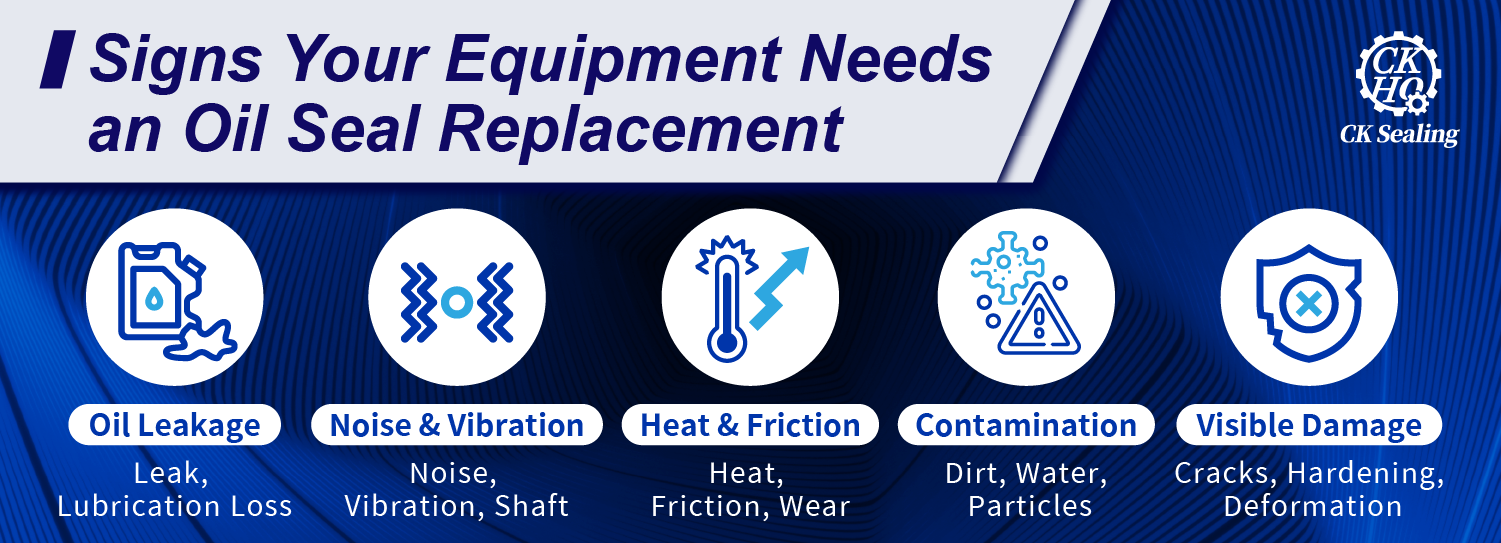

Signs Your Equipment Needs an Oil Seal Replacement

Whenever I inspect machinery, I always remind people that oil seals behave a lot like small protective guards inside a machine. When they start to fail, they usually send clear warning signs long before the damage becomes catastrophic.

Ignoring those signals can lead to serious issues such as overheating, loss of lubrication, mechanical failure, or even unexpected downtime that costs far more than a simple replacement.

Below are the signs I pay closest attention to when determining whether it is time to replace an oil seal. These indicators apply across automotive systems, industrial equipment, and heavy machinery. They are also the same warning flags that top oil seal manufacturers and oil seals suppliers emphasize in their maintenance guides.

Oil Leakage or Excessive Lubrication Loss

The most obvious sign is leakage. If I start noticing oil around a rotating shaft, gearbox housing, or pump assembly, it tells me the seal has lost its ability to maintain a tight barrier.

Common causes include:

- Worn sealing lips

- Hardened rubber due to heat or aging

- Shaft misalignment

- Pressure fluctuations

- Incorrect material selection

Oil leakage is a clear indication that the seal can no longer do its job. Lip seal manufacturers often warn that even a small leak can snowball into serious mechanical failure because lubrication levels drop faster than operators expect.

Unusual Noise or Vibrations Around Rotating Shafts

When a machine starts making unusual sounds, I treat it like a car making strange noises under the hood. Something is not right. With oil seals, noise or vibration often indicates that the sealing lip is worn or that the shaft surface has developed irregularities.

Typical symptoms include:

- Whining or scraping sounds

- Intermittent vibration around the housing

- Rough rotation when the shaft is turned manually

These issues usually appear when a seal loses flexibility or when debris enters the sealing area. High-quality oil seal manufacturers design lips with specific geometries to reduce friction and maintain stable contact. When that geometry wears down, noise becomes one of the first noticeable signals.

Increased Friction, Wear, or Heat

One of the quickest ways I detect a failing oil seal is by checking for heat around the sealing area. Excess heat tells me that friction has increased, usually because the sealing lip is damaged or the lubricant can no longer reach critical surfaces.

Signs include:

- Excessive heat around bearings or housings

- Burnt lubricant smell

- Unusual shaft drag or resistance

If friction continues unchecked, it often leads to bearing damage or shaft scoring. This is why many oil seals suppliers recommend regular thermal checks during preventive maintenance.

Contamination of Oil or Lubricants

When contaminants such as dirt, dust, metal particles, or moisture start appearing inside the oil reservoir, it tells me the seal is no longer protecting the system. Oil seals are designed to keep contaminants out while keeping lubrication in. If either side fails, the entire lubrication system becomes compromised.

Common contamination sources include:

- Breached sealing lip

- Cracked seal casing

- Damaged dust lip

- Improper installation

A contaminated lubrication system can shorten equipment lifespan dramatically. Most reputable lip seal manufacturers stress the importance of replacing seals immediately when contamination starts appearing.

Visible Damage or Cracks on Seal Surface

Whenever I perform a visual inspection, I look closely at the seal surface. Damage is often obvious before performance problems even appear. If I see cracks, flattening, hardened rubber, or missing chunks of material, that tells me the seal has reached the end of its usable life.

Common visual failures include:

- Cracked or brittle rubber

- Torn or deformed sealing lip

- Swollen elastomer from chemical exposure

- Excessive wear lines

Any visible damage means the seal is no longer reliable. Oil seal manufacturers produce technical manuals that clearly state that physical deterioration is a sign of immediate replacement, not something to monitor later.

FAQ: Common Questions About Oil Seal Manufacturers

I hear a lot of recurring questions from engineers, mechanics, and procurement teams when they start comparing oil seal manufacturers. Choosing a seal might look simple on the surface, but once you dig into materials, certifications, and performance requirements, the buying decision becomes a lot more technical.

Below are the answers I usually give when someone wants clear, practical guidance.

Who makes the most durable oil seals in 2026?

The most durable oil seals in 2026 usually come from manufacturers that invest heavily in advanced materials and automated production. The brands that stand out for durability are the ones with strong control over their rubber compounds, metal casings, and bonding processes.

The manufacturers I trust most are those that provide:

- FKM or PTFE options for high heat

- Consistent quality supported by IATF 16949 certifications

- Full testing reports for pressure, speed, and temperature

Durability often comes down to engineering precision. Many of the top oil seals suppliers partner directly with leading lip seal manufacturers so they can guarantee performance in harsh environments such as engines, gearboxes, industrial pumps, and hydraulic systems.

Are OEM oil seals better than aftermarket brands?

OEM seals are designed specifically for the original equipment, so they usually fit perfectly and follow strict quality standards. That said, many aftermarket oil seal manufacturers produce seals that perform just as well or even better, especially when they use premium elastomers or upgraded lip designs.

Here is how I usually compare them:

OEM seals

- Perfect fit for the equipment

- Tested under the original engineering specifications

- Higher cost in most cases

Aftermarket seals

- Often available in advanced materials such as HNBR or PTFE

- Competitive price

- Wide selection for custom applications

If I need a perfect match for a high-value machine, I choose OEM. If I want improved performance or a more cost-effective option, I look at reputable aftermarket lip seal manufacturers.

What materials are best for high-temperature applications?

For high-temperature applications, material selection is everything. I choose materials the same way I choose protective gear for extreme weather. If the heat is intense, the material has to survive without hardening, cracking, or losing elasticity.

The best materials for high heat include:

- FKM for automotive engines

- PTFE for extremely high speeds and chemical resistance

- HNBR for hot industrial environments

- ACM for transmission systems

Most high-end oil seal manufacturers offer these materials because they remain stable where standard NBR seals would quickly degrade. If a seal needs to survive long-term exposure to extreme heat, PTFE and high-grade FKM are usually the safest choices.

How often should industrial oil seals be replaced?

Replacement intervals depend heavily on the equipment type, operating conditions, and environmental exposure. As a general guideline, I follow these timeframes:

- Standard industrial machinery:Replace seals every one to three years depending on rotation speed and temperature.

- High-load or high-temperature systems:Replace seals during every major maintenance cycle.

- Hydraulic equipment:Replace seals when performance drops or contamination appears.

- Automotive systems:Replace seals during major engine or transmission service intervals.

Most oil seals suppliers recommend scheduled inspections every few months for heavy machinery. If I notice heat buildup, leaks, or contamination, I replace seals immediately rather than waiting for a total failure.

Can I order custom oil seals in small quantities?

Yes, many oil seal manufacturers offer custom seals even in small batches. In fact, small quantity custom orders are becoming more common because industries need specialized dimensions, lip profiles, or materials for modern equipment.

Typical custom options include:

- Special outer casing shapes

- Unique lip geometries

- Nonstandard diameters

- PTFE or FKM blends for extreme conditions

- Custom colors or hardness levels

Smaller production runs do cost more per unit, but many lip seal manufacturers provide rapid prototyping and fast tooling options. For unique projects or low-volume machines, this flexibility can save a lot of time and prevent compatibility issues.

Still deciding which oil seal manufacturer to partner with?

CK Sealing is a Taiwan-based manufacturer specializing in high-quality oil seals and precision sealing solutions. The company focuses on designing and producing a wide range of sealing products, including rotary shaft seals, hydraulic seals, O-rings, customized rubber components, and high-performance sealing parts for industrial applications.

CK Sealing is known for stable quality, strict ISO-certified production processes, and strong OEM / ODM capabilities. Their sealing products are widely used in automotive systems, industrial machinery, agricultural equipment, construction machinery, and various high-load and high-temperature environments.

With continuous innovation, advanced material engineering, and reliable durability, CK Sealing aims to deliver safe, long-lasting, and high-performance sealing solutions for global manufacturers.

If you have any oil seal sourcing needs, feel free to contact CK Sealing — the team will be glad to discuss your requirements in detail!

Contact Us:https://cksealing.com/